Where are you: type 69 hydraulic bending machines?

The other day at Röthlisberger Haustechnik in Bützberg: Roman Röthlisberger and the type 69-M-6/1 bending machine welcomed two chaps from Jorns AG. We have now received the report from the hydraulic bending machine – with a request. Can anyone help?

Type 69-M-6/1 bending machine: built around 1973

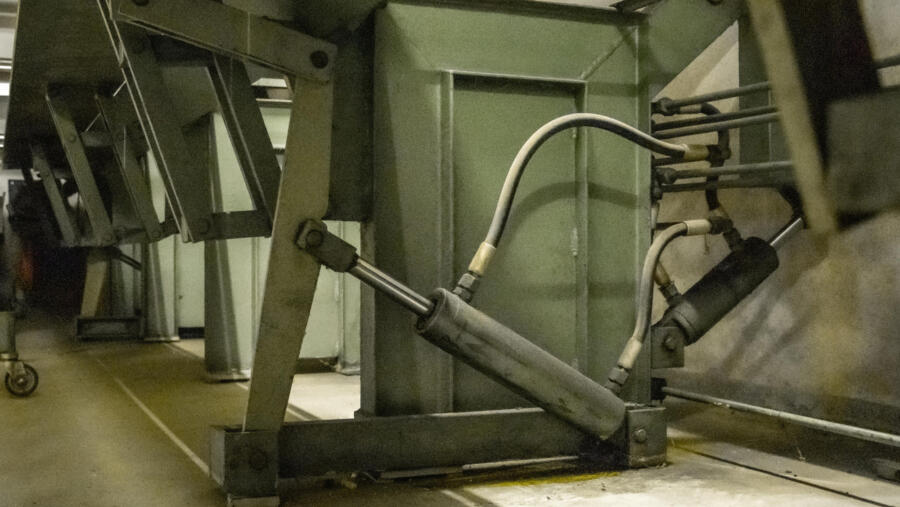

Type 69-M-6/1 bending machine: a glance beneath the machine

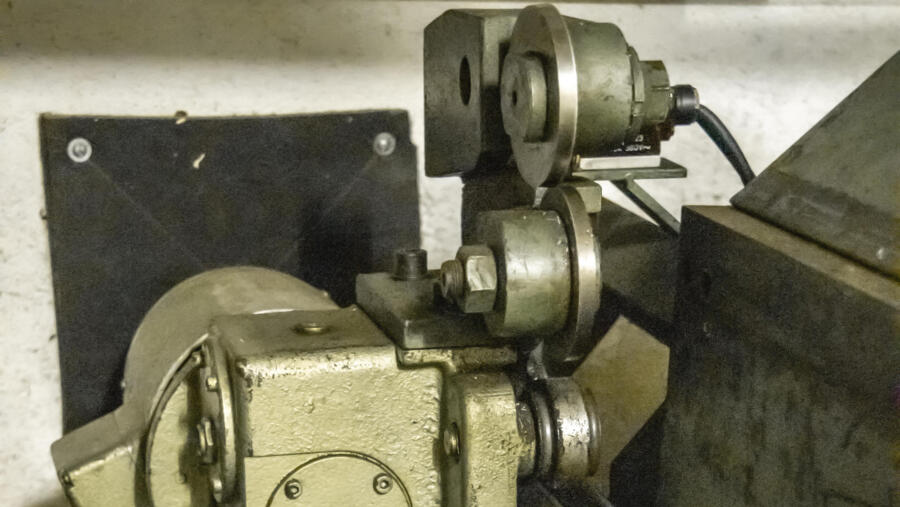

Type 69-M-6/1 bending machine: the electrically powered roll shears

Type 69-M-6/1 bending machine: the automatic cable feed

Type 69-M-6/1 bending machine: the hydraulic lever control

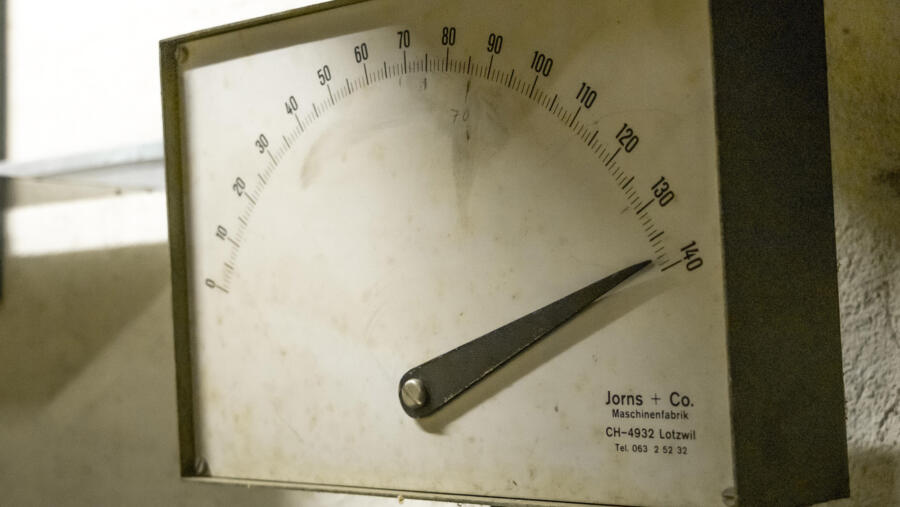

Type 69-M-6/1 bending machine: the angle display

Type 69-M-6/1 bending machine: working with the mobile phone

Hello, I’m a type 69-M-6/1 hydraulic bending machine – of just type 69 to you!

It all began a few days ago. Roman burst through the door at the crack of dawn – with that typical Roman look in his eye. I knew straight away that something good was going to happen that day. Luckily, I had already stretched my bending linkages and arms to their full six metres and oiled them in preparation. I was more than ready. It’s not often I get a visit from the boss himself because he’s now more of a house technician than a tinsmith. A pity really, because I really love bending and edging. Want to show everyone that I haven’t lost it yet. Far from it!

Roman came back again at midday with two chaps from a certain Jorns AG. Okay, so it won’t be that exciting after all, I thought to myself. But then I realise that these two are somehow different. One of them had hair on his main controller and the other didn’t. When I saw their nameplate, it suddenly dawned on me: Strike! They're from my original workshop in Lotzwil. How cool is that? The place I was originally built nearly 50 years ago. I can’t control a little squeak of excitement and the visitors now recognise me. One of them looks quite proud and says:

“This type of machine was developed in 1969 and is one of the first generation of bending machines from Lotzwil with a parallelogram as a bending linkage.”

“This hydraulic bending machine is a further development, probably from 1973, because it’s hydraulically powered and has electric shears with an automatic cable feed.” Boy oh boy, I was so happy it was all I could do to stop myself from hugging him with my clamping tools. At long last, Roman switched me on. My hydraulic pump started straight away, from nought to sixty. A regular, majestic hum filled the room. Things fell quiet as we all just enjoyed the sound.

“Look, how cute, these levers and handles remind me of those little excavators you can find on children’s playgrounds”,

said the other chap. Cheeky so-and-so – children’s playground indeed! Although, wait a minute … I really was part of the children’s playground for Roman when he was knee-high to a grasshopper. That would have been in the days of the senior-senior-boss, Mr Rémy …

“I still remember when I was allowed to help grandfather on the bending machine,” chipped in Roman. “He paid 25,800 francs for it, a fortune for us in those days.” But that meant that Röthlisberger were the only tinsmiths in the area who could bend thin sheets up to 1 millimetre over 6 metres precisely with their hydraulic bending machine for many years – I hum along. And just keep on humming. They are now talking shop about my bending angle display and the electric roll shears. And that little electronic thingy, you know, mobile phone, keeps taking photos of me. I get on really well with this mobile phone – keeping track of what’s going on on a building site or reading a construction profile someone has sent it. I haven’t felt this fresh and young for ages!

That bald chap from Jorns has just called me an “old lady.” All because my shears don’t have a new-fangled servo drive. So what! I was around when he still had curls to call his own! It’s enough to nearly turn me off. But wait a minute. He’s just said something more interesting:

“Hundreds of hydraulic bending machines like this one are still in use – in Switzerland and elsewhere around the world.”

Oh wow, my bending tool has come out in a hot flush – all these years and I never thought of that. If that's true, maybe I could get to see some of my old colleagues again who are still working as hydraulic bending machines in workshops!

So here’s my request: do you have a bending machine from my generation, a type 69, in your workshop?

Or perhaps in your stores? If so, please get in touch, best of all with a photo of the hydraulic bending machine and your contact data. The chaps from Jorns are planning something – I don’t know what but I love a surprise and am looking forward to seeing plenty of old friends!

Do you have a type 69 hydraulic bending machine? If so, send us a photo!

Include info about the exact type if possible and your contact data. We will be raffling off 69 surprises out of all entries.* We’re looking forward to hearing from you!

* The judge’s decision is final.

Profile: type 69-M-6/1 hydraulic bending machine

- First generation hydraulic bending machine, Jorns AG, formerly the firm of Konrad, year of construction: around 1973; no machine frame available yet, machine stands placed on metal plates and bolted directly to the ground.

- Machine capacity: Bending capacity up to 1 mm, bending length up to 6 m

- Lever control; drive: hydraulic pump

- Bending angle of the bending tool driven by a side pull, angle displayed in a separate box

- Electrically-powered roil shears: on separate shears station with electric motor

- Special features: parallelogram as bending linkage; shear station cable reel with automatic feed