„Smart production - Industry 4.0 for modern roofing businesses and sheet metal trim companies.“

You want to accelerate your order processing and production by up to 400%? You want to save expenses and time in your production and administration? This makes you think like numerous other companies. A factual report about a simple, proven, turnkey solution:

Complete solution for small entrepreneurs up to large corporations

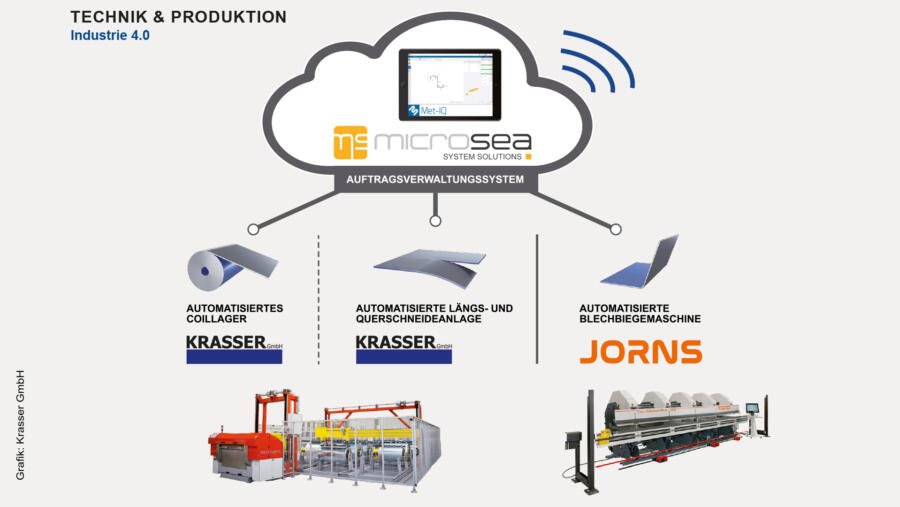

Krasser GmbH, in cooperation with Jorns AG and MicroSea System Solutions GmbH, offer the ideal and absolute affordable complete solution for small entrepreneurs up to large corporations. The MetIQ-Software by MicroSea System Solutions GmbH is unique on the market and combines the double bending machines from Jorns AG with the fully-automatic coil-handling and CENTURIO sheet metal cutting machine from Krasser GmbH. Hereby flexible, efficient and almost waste-less work becomes a reality. Plug- and Play-so to speak.

Customers are impressed about the transparency, backtracking and simplicity of the order processing:

You enter the required geometry and dimensions into the MetIQ-Software via mobile device directly at the construction site or on a PC in your production planning. The software system is also capable of indicating warnings in case of machine or material limitations that won’t allow the production of a created part shapes. MetIQ fully-automatically calculates the bend allowance and immediately derives the precise cut for the CENTURIO as well as the accurate folding program for the TWINMATIC. The cutting job order will subsequently be transmitted to the CENTURIO cutting machine with fully-automatic coil-handling to supply the requested sheet metal to the slitting machine in an ergonomic, quick and damage-free way. An optimal cutting quality can be guaranteed as well as the productional waste is minimized due to the fully-automatic knife positioning, cutting gap adjustment and immersion depth adjustment dependent on individual sheet metal types at the CENTURIO system. A labeling unit of the CENTURIO applies an adhesive label to every cut-to-size piece. The label can include a picture of the finished part as well as dimensions and a QR-code, which will be scanned by the double bending machines from Jorns AG and your order will be processed fully-automatic and correct. The QR-code can include information of the customer such as name, delivery address, project number or any other possible assembly instruction notes. Also a full integration to a production planning system, ERP-system, an accounting system and tracking system is easily possible due to offered interfaces.

Preconfigured standard profiles or construction-specific sheet metal components, everything is herewith possible!

In general, every individual machine system already offers added value itself in your production. The perfectly “Plug & Play”-combination of Jorns AG, Krasser GmbH and MicroSea System Solutions GmbH however results in an unbeatable and unprecedented added value in a modern production. The “production of the future” has become reality with this system constellation. Expensive production errors and piles of papers are history – thanks to digitalization!

Make the right investment and benefit from the smart production of the future!