From a folding rule to a CNC-controlled bending machine with back stop – a story to make you think again

Anyone who measures up profiles with a folding rule every time can produce some real masterpieces. But what can a CNC-controlled bending machine with back stop do more automatically? The master tinsmith in this story wanted to find out the truth. Read on to learn about what he also discovered alongside the advantages and disadvantages.

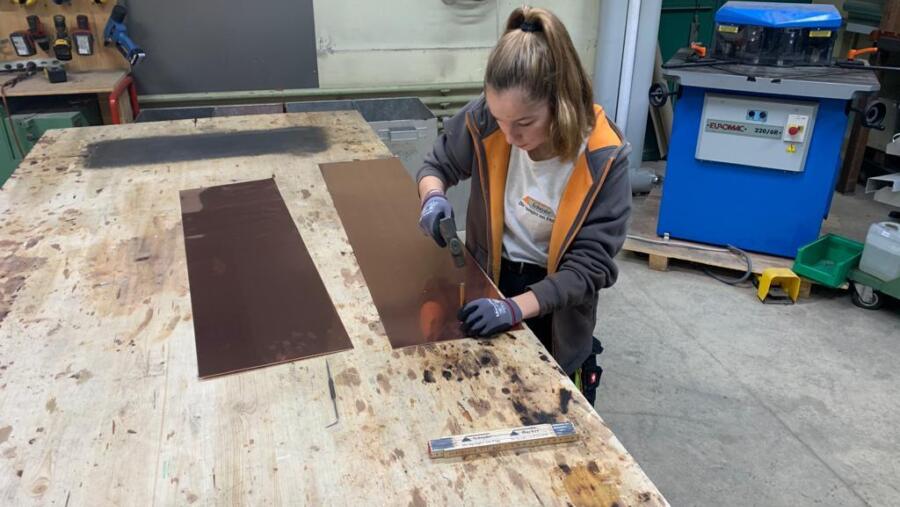

Young tinsmith during calibration, Spenglerei Schnyder AG

Young tinsmith during centre punching, Spenglerei Schnyder AG

A master tinsmith who had spent all his life measuring profiles by hand with a folding rule had finally had enough. “I love my double metre stick,” he thought to himself. “Every profile is a masterpiece. But the repeat precision and speed sometimes leave a lot to be desired …” Which is why he summoned his three apprentices and said: “Find out all you can about every long, hydraulic bending machine – with and without a back stop. We are going to compare them. I can’t wait to see what they can do.”

The apprentices swarmed out – onto the Internet – and were more than happy to do what they had been told. After all, surfing the web to do some research for the master is firstly great fun. And secondly, the manual bending machines in the workshops were frankly more than just retro. With a hand wheel! It’s a little embarrassing when a friend from school dropped by. Other tinsmith workshops had bending machines with a back stop as standard – some of them were even huge. It was like being in Disneyland!

“It’ll be a robot nightmare,” thought the master tinsmith with a shudder, “like being taken over by aliens.” Even though he had just given his apprentices precise instructions, he suddenly felt he should put a stop to things at the thought of the future of his workshop:

“We need a new bending machine. But who here can program it?”

The apprentices soon appeared before their master again. One after the other, they presented their findings – all kinds of names for machines and fantastic descriptions flew back and forth. “And what do you recommend?” asked the master eventually. “Well, there is one CNC-controlled bending machine that can be between four and twelve metres long,” said the first starry-eyed. “With a graphic control system, back stop system, servo-drive …” “Yeah, and the tapered back stop is really good; you can use it to bend even longer, parallel, tapered or overlapped profiles,” said the second. “And everything’s automatic, you don’t need a folding rule anymore.”

This is what the master tinsmith had hoped to hear – and hoped not to hear. “But we’re tinsmiths, not IT specialists,” he cried. “Oh, but we are,” blurted out the third apprentice. “We’re both – tinsmith’s apprentices today learn about computers in school. And with the right training, we can become experts and program a CNC bending machine for any order. It can then help us to perform endless repetitions exactly. No more countless individual pieces like now!” Of course, only the tinsmith’s daughter could talk this way! She knew about her father’s dilemma and quickly added: “But of course, we’ll still keep the double metre stick because we’ll still have to measure angles and perform calculations in future, dad.” Smiles all round. Even on the master’s face! So it would seem there were still people who were eager to learn this new tinsmith’s work. And there wouldn’t be an official “burning of the rule” ceremony if he bought a new CNC-controlled bending machine with back stop. And joking apart, one thing was clear:

the highly talented bending machine with back stop was a friend and helper – not an unknown intruder.

The master tinsmith now expectantly turned his attention to the list with all of the advantages and disadvantages: a comparison of folding rule v. back stop. “Well done! Let’s see what we can get out of a bending machine with a back stop.”

Are you interested in the comparison of “folding rule v. back stop”? If so, don’t forget to read our next news.

What do you wish from your future work? We would be happy to help.

Your author

Category

Keywords

calibration with folding rule, bending machine with backstop, bending machine without backstop