A short history of bending machines – Part 1

From the beginnings of sheet metal processing to the first bending devices in the Middle Ages. The history of bending machines actual starts way back in ancient times.

Antique helmet – made by forging a thick circular sheet of metal | © dcw25 – stock.adobe.com

Historic hammer forge in Tyrol | © hubert – stock.adobe.com

Old wooden workbench with integrated vices | © juriskraulis – stock.adobe.com

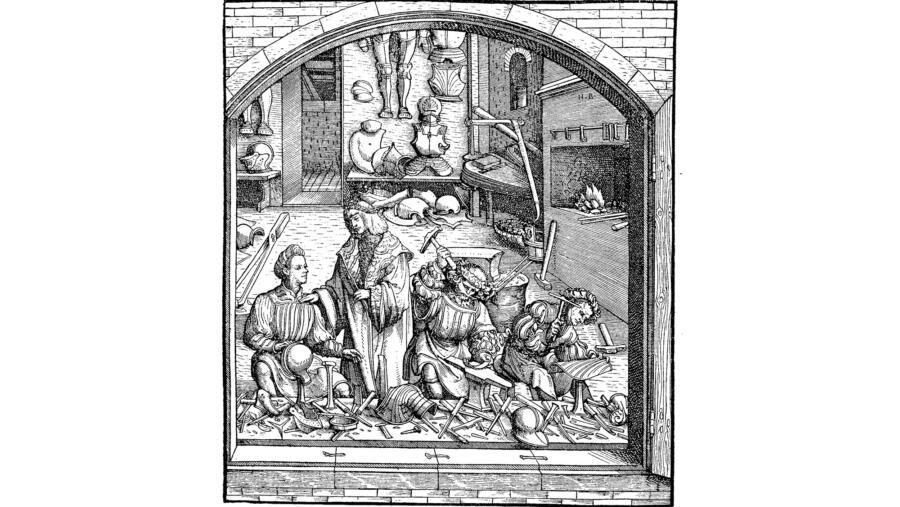

A gunsmith's workshop around 1500, reproduction of a woodcut by Hans Burgkmair. © Sunny Celeste / Alamy Stock Foto

But first, a definition – what is a bending machine?

“Bending machine, a machine tool to shape spatial workpieces from flat or rod-shaped initial material without cutting: metal plates, strips, rods, tubes etc.”

From: Meyers Großes Universallexikon.

In the ancient world: sheet metal processing with divine fire

The history of bending machines can be traced back to ancient times. Sheets of copper, gold, silver and all kinds of alloys were forged. Hammering, also called repoussage or chasing, was employed to shape, bend and make numerous items: coins, jewellery, tools, everyday objects, arms and armour parts.

Sheet metal products were very popular in ancient times and blacksmiths were highly-respected specialists. Hephaestos, the Greek god of metalworking, was the only craftsman among the gods who was also responsible for fire.

People continued hammering for centuries – by hand and with water power

The blacksmith’s craft spread and metalworking technology continued to develop. From the 11th century onwards, metal was not only hammered by hand. It now became possible to manufacture and process steel sheets in large quantities. Huge hammers in water-powered hammer forges took over the really hard work – making it easier and more efficient to manufacture commodities. “It only became possible to produce larger panels of around 500 by 500 mm with a thickness of < 1mm with the help of these mechanical hammers,” writes Gerd Ising about the historical development of metal bending on brakes.

Mediaeval sheet metal processing: between workbench and vice

So, the metal sheets were available and people were busy bending and shaping them. They did so – and it can still be done today – on any well-equipped workbench; it could even be a simple wooden table a carpenter's bench. The thin metal was, and still is, shaped freely: it is practically brought into the desired shape over an edge with a hammer.

However, the work began to be divided up following the foundation of the guilds. The blacksmith no longer had to produce and process the metal sheets, this was now done by the sheet fabricators. A number of different professions emerged, some of which still exist to day, or in a similar form: ornamental metalsmiths and goldsmiths through to tinsmiths, tinkers, whitesmiths and tinners. A woodcut from around 1500 impressively documents the state of manufacturing technology in the pre-industrial age: in this view of a gunsmith’s workshop, the special shaping and flaring tools can also be seen very clearly.

The invention of the vice at the beginning of the 16th century meant that it was then possible to bend thicker or narrow sheets – but obviously only over the width of the vice jaws.

A bigger solution had to be found for larger sheets. It looked something like this in mediaeval workshops: the sheet was clamped between two wooden beam with threaded rods made of wood and then worked with a hammer. A second beam was sometimes attached to the lower beam with a leather strap that could be used to bend the sheet around the upper beam. Unfortunately, not only the sheet but also the complete beam was sometimes bent.

The history of the bending machine continues – read Part 2:

The history of the bending machine: from the Industrial Revolution to the present day

Do you have anything to add to the history of the bending machine? Let us know.

Sources

Meyers Großes Universallexikon, Volume 2, page 424, Bibliographisches Institut AG, Mannheim 1981

Gerd Ising, Die Schwenkbiegemaschine, Books on Demand GmbH, Norderstedt 2005

Wikipedia, Hammer mill, https://en.wikipedia.org/wiki/...